The Enduring Quest: Revolutionizing Electric car Battery Recycling

The electric vehicle (EV) revolution is upon us, promising a cleaner, more sustainable future. Yet, lurking beneath the gleaming surface of these technological marvels lies a significant challenge: the disposal and recycling of their massive lithium-ion batteries. As the number of EVs on our roads explodes, so too does the looming mountain of spent batteries, posing both environmental and economic dilemmas. This comprehensive examination delves into the complex world of electric car battery recycling, exploring the technologies, challenges, and potential solutions that will shape the future of sustainable transportation.

The Growing Battery Mountain: A Ticking Time Bomb?

The heart of every EV is its battery, a complex assembly of rare and valuable materials like lithium, cobalt, nickel, and manganese. These materials, crucial for energy storage, are finite resources, and their extraction often carries a heavy environmental footprint. As first-generation EV batteries reach the end of their lifespan, the sheer volume of spent units is set to increase dramatically. Predictions suggest millions of tons of batteries will require disposal or recycling in the coming decades, creating a pressing need for robust and scalable solutions.

The Environmental Imperative: Beyond the Tailpipe Emissions

The environmental benefits of EVs are often touted as a reduction in tailpipe emissions. However, the lifecycle of an EV battery, from raw material extraction to disposal, presents its own set of environmental concerns. Improper disposal can lead to soil and water contamination due to the leaching of heavy metals and electrolytes. Moreover, the energy-intensive processes involved in mining and refining battery materials contribute to greenhouse gas emissions. Recycling offers a crucial pathway to mitigating these impacts, reducing the need for virgin materials and minimizing waste.

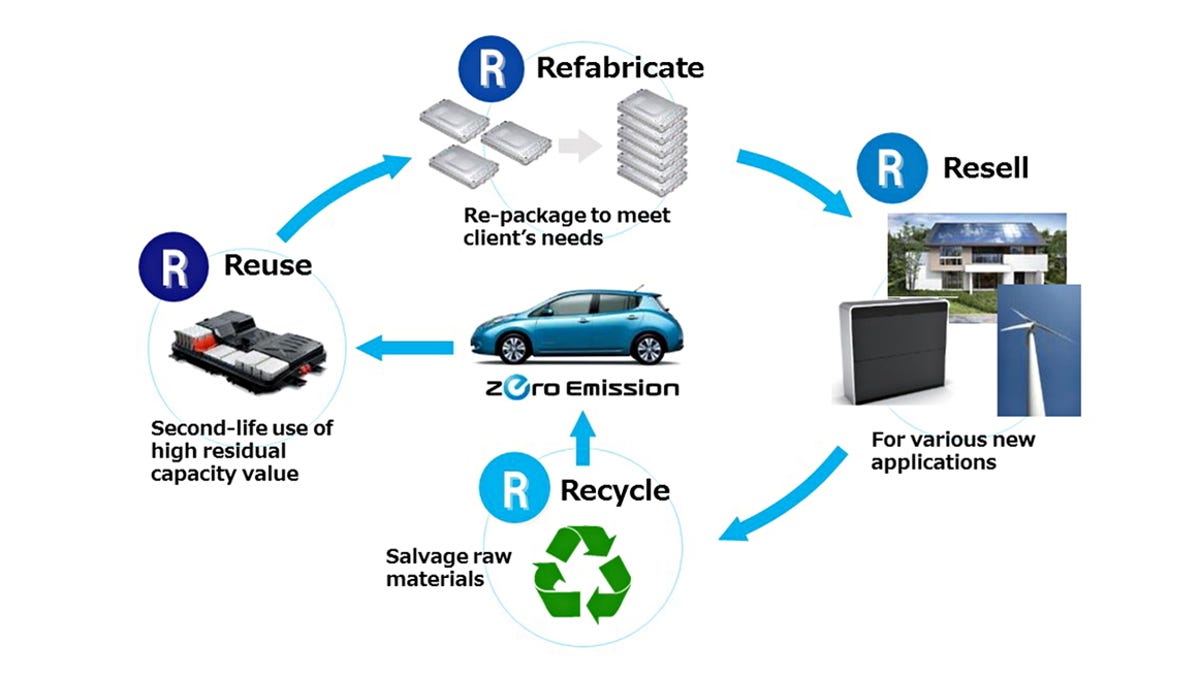

The Economic Opportunity: A Circular Economy for Batteries

Beyond environmental considerations, battery recycling holds immense economic potential. Recovering valuable materials from spent batteries can create a closed-loop supply chain, reducing reliance on volatile global markets and securing access to critical resources. This circular economy approach can foster innovation, create jobs, and enhance the sustainability of the EV industry.

The Challenges of Battery Recycling: A Complex Puzzle

Recycling EV batteries is not a straightforward process. These batteries are complex, varied in design and chemistry, and often hazardous to handle. Several key challenges hinder the development of a robust recycling infrastructure:

Battery Chemistry and Design Variations: A Recycling Nightmare

EV batteries come in diverse chemistries, each requiring specific recycling processes. The lack of standardization in battery design and composition complicates the development of universal recycling technologies.

Collection and Transportation Logistics: A Fragmented System

Establishing efficient collection and transportation networks for spent batteries is crucial. This requires collaboration between manufacturers, dealerships, recyclers, and policymakers to create a seamless and accessible system.

Dismantling and Pre-treatment: A Labor-Intensive Process

Disassembling EV batteries is a complex and potentially hazardous task, requiring specialized equipment and skilled labor. Automation and efficient pre-treatment processes are essential for scaling up recycling operations.

Recovery Technologies: Bridging the Gap Between Research and Industry

Several recycling technologies are under development, each with its own advantages and limitations. These include:

Pyrometallurgy: High-Temperature Smelting

Pyrometallurgy involves heating batteries to high temperatures to extract valuable metals. While effective for recovering certain metals, it is energy-intensive and can result in significant emissions.

Hydrometallurgy: Chemical Leaching

Hydrometallurgy uses chemical solvents to dissolve and separate battery materials. It offers higher recovery rates and lower energy consumption compared to pyrometallurgy but requires careful management of chemical waste.

Direct Recycling: Regenerating Cathode Materials

Direct recycling aims to regenerate the cathode materials directly, minimizing the need for extensive chemical processing. This approach holds promise for reducing energy consumption and material losses.

Economic Viability: Balancing Costs and Benefits

The economic viability of battery recycling depends on several factors, including the cost of collection, transportation, processing, and the market value of recovered materials. Developing cost-effective and scalable recycling technologies is crucial for ensuring the economic sustainability of the industry.

Policy and Regulatory Frameworks: Driving the Transition

Governments and regulatory bodies play a vital role in shaping the future of battery recycling. Clear and consistent policies are needed to:

Mandate Battery Recycling Targets: Setting Clear Goals

Establishing mandatory recycling targets can drive investment and innovation in recycling technologies.

Implement Extended Producer Responsibility (EPR): Shifting the Burden

EPR policies require manufacturers to take responsibility for the end-of-life management of their products, incentivizing them to design batteries for recyclability.

Standardize Battery Design and Labeling: Facilitating Recycling

Standardizing battery design and labeling can simplify collection, sorting, and processing.

Promote Research and Development: Fostering Innovation

Investing in research and development of advanced recycling technologies is crucial for improving efficiency and reducing costs.

The Role of Industry Collaboration: Building a Sustainable Ecosystem

Collaboration between industry stakeholders, including battery manufacturers, automakers, recyclers, and research institutions, is essential for building a sustainable battery recycling ecosystem. Sharing knowledge, best practices, and resources can accelerate the development and deployment of innovative recycling solutions.

The Future of Battery Recycling: A Vision for Sustainability

The future of EV battery recycling hinges on the development of efficient, cost-effective, and environmentally friendly technologies. By embracing a circular economy approach, we can minimize the environmental impact of EVs, secure access to critical resources, and create a more sustainable transportation future.

Advancements in Automation and AI: Enhancing Efficiency

Automation and artificial intelligence (AI) can play a crucial role in enhancing the efficiency of battery dismantling, sorting, and processing. AI-powered systems can optimize recycling processes, reduce labor costs, and improve material recovery rates.

Development of Next-Generation Recycling Technologies: Closing the Loop

Continued research and development of advanced recycling technologies, such as direct recycling and bio-leaching, are essential for closing the loop and minimizing waste.

Second-Life Applications: Extending Battery Lifespan

Exploring second-life applications for used EV batteries, such as stationary energy storage, can extend their lifespan and delay the need for recycling.

Consumer Awareness and Engagement: Driving Change

Raising consumer awareness about the importance of battery recycling and encouraging responsible disposal practices is crucial for driving change.

The Path Forward: A Collaborative Effort

The transition to a sustainable battery recycling ecosystem requires a collaborative effort from all stakeholders. By investing in research, developing robust policies, and fostering industry collaboration, we can transform the challenge of EV battery disposal into an opportunity for innovation and sustainability. The future of electric vehicles depends not only on their ability to reduce emissions but also on our ability to manage their lifecycle responsibly. As we accelerate towards an electrified future, the imperative to build a circular economy for batteries becomes ever more critical.