“`markdown

# The Silent Revolution: A Deep Dive into Electric car Engines

The automotive landscape is undergoing a seismic shift, driven by the relentless march of electric vehicle (EV) technology. At the heart of this revolution lies the electric car engine, a marvel of engineering that promises a cleaner, quieter, and more efficient future for transportation. This comprehensive article delves into the intricacies of electric car engines, exploring their design, operation, advantages, challenges, and the cutting-edge innovations that are shaping their evolution.

Understanding the Fundamentals: What is an Electric Car Engine?

Unlike traditional internal combustion engines (ICEs) that rely on the controlled explosion of fuel to generate power, electric car engines, more accurately referred to as electric motors, convert electrical energy into mechanical energy. This fundamental difference underpins the numerous advantages of EVs, including zero tailpipe emissions and superior efficiency.

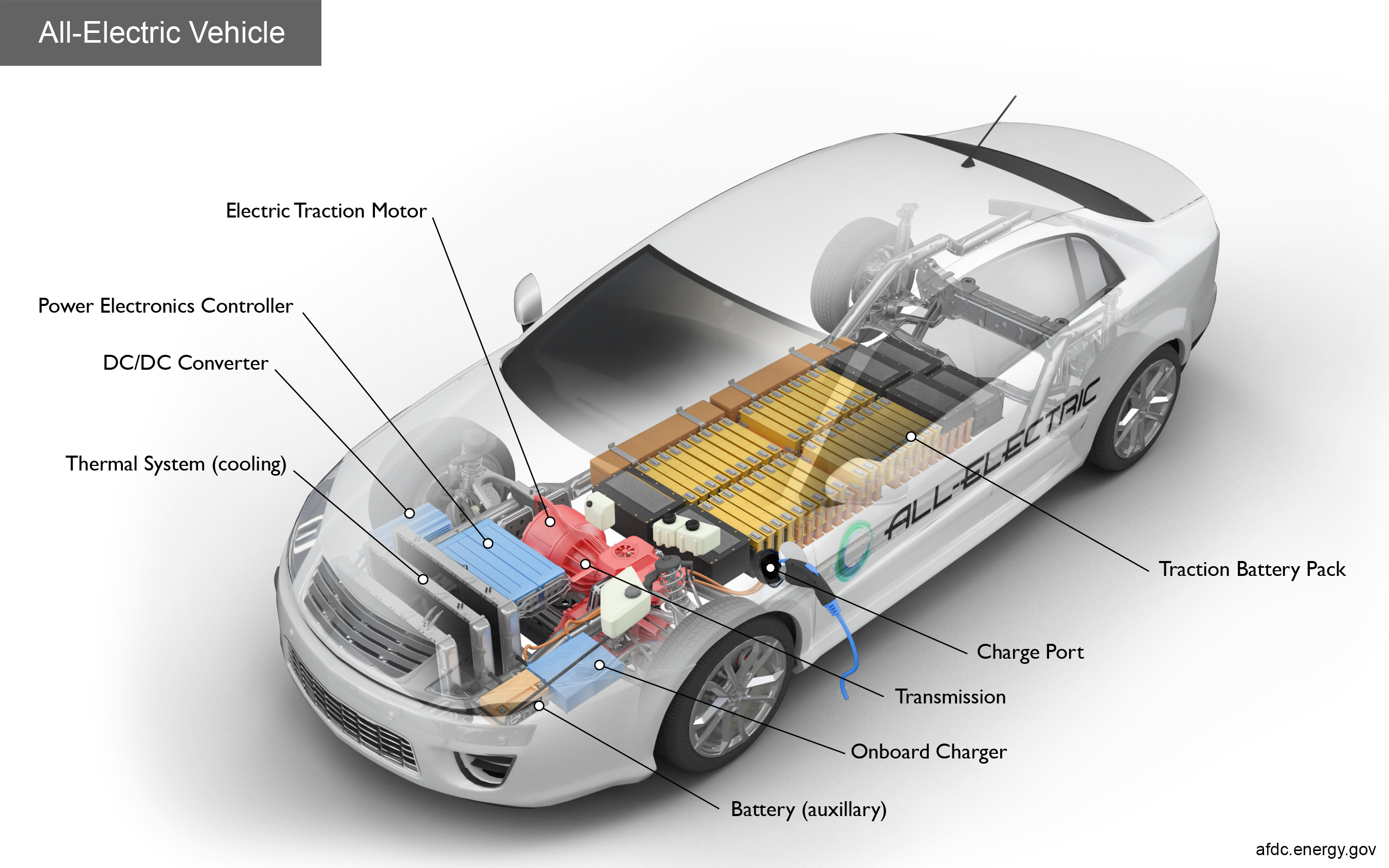

Key Components of an Electric Motor

An electric motor comprises several essential components that work in harmony to produce motion:

Stator: The Stationary Part

The stator is the stationary part of the motor, typically consisting of windings of copper wire arranged in a specific pattern. When an electric current is passed through these windings, they generate a magnetic field.

Rotor: The Rotating Part

The rotor is the rotating part of the motor, interacting with the magnetic field generated by the stator. It can be a permanent magnet rotor or an induction rotor.

Permanent Magnet Rotor

Uses permanent magnets to create its own magnetic field. This type of motor is highly efficient and offers excellent torque density.

Induction Rotor

Uses induced currents in its windings to create a magnetic field. These motors are robust and cost-effective but generally less efficient than permanent magnet motors.

Commutator and Brushes (in DC Motors)

In direct current (DC) motors, a commutator and brushes are used to switch the direction of current in the rotor windings, ensuring continuous rotation. However, most modern EVs utilize alternating current (AC) motors, eliminating the need for these components.

Inverter: Converting DC to AC

The inverter is a crucial component that converts the direct current (DC) from the battery into alternating current (AC) required by the motor. It also controls the frequency and voltage of the AC, thereby regulating the motor’s speed and torque.

How Electric Car Engines Work: A Step-by-Step Explanation

The operation of an electric motor can be summarized in a few key steps:

Battery Power Supply

The process begins with the battery pack, which stores electrical energy in the form of DC.

Inverter Conversion

The inverter converts the DC from the battery into AC, adjusting the frequency and voltage based on the driver’s input (accelerator pedal).

Magnetic Field Interaction

The AC current flows through the stator windings, generating a rotating magnetic field. This field interacts with the magnetic field of the rotor.

Rotor Rotation

The interaction between the stator and rotor magnetic fields causes the rotor to rotate, converting electrical energy into mechanical energy.

Power Transmission

The rotating rotor drives the transmission, which then transfers power to the wheels, propelling the vehicle forward.

Advantages of Electric Car Engines

Electric car engines offer a plethora of advantages over traditional ICEs, making them a compelling choice for the future of transportation:

Zero Tailpipe Emissions

Electric motors produce zero tailpipe emissions, contributing to cleaner air and a healthier environment.

High Efficiency

Electric motors are significantly more efficient than ICEs, converting a larger percentage of energy into motion.

Instant Torque

Electric motors deliver instant torque, providing rapid acceleration and a responsive driving experience.

Quiet Operation

Electric motors operate quietly, reducing noise pollution and creating a more serene driving environment.

Reduced Maintenance

Electric motors have fewer moving parts than ICEs, resulting in lower maintenance costs and increased reliability.

Regenerative Braking

Electric motors can act as generators during braking, recovering kinetic energy and recharging the battery.

Challenges and Limitations

Despite their numerous advantages, electric car engines also face certain challenges:

Battery Technology

Battery technology remains a key area of focus, with ongoing research aimed at improving energy density, charging speed, and lifespan.

Charging Infrastructure

The availability of charging infrastructure is crucial for widespread EV adoption, requiring significant investment in public and private charging stations.

Range Anxiety

Concerns about driving range and the availability of charging stations can deter potential EV buyers.

Raw Material Sourcing

The production of electric motors and batteries requires raw materials, some of which are sourced from environmentally sensitive regions.

Recycling and Disposal

Proper recycling and disposal of electric motors and batteries are essential to minimize environmental impact.

Types of Electric Motors Used in EVs

Electric vehicles utilize various types of electric motors, each with its own characteristics and applications:

Permanent Magnet Synchronous Motors (PMSMs)

PMSMs are the most common type of motor used in modern EVs, offering high efficiency and torque density.

Induction Motors (IMs)

IMs are robust and cost-effective, but generally less efficient than PMSMs. They are used in some older EV models.

Switched Reluctance Motors (SRMs)

SRMs are simple and robust, with no permanent magnets or windings in the rotor. They are gaining attention for their potential in future EV applications.

Axial Flux Motors

Axial flux motors have a compact design and high torque density, making them suitable for applications where space is limited.

Innovations and Future Trends

The field of electric motor technology is rapidly evolving, with ongoing research and development focused on improving performance, efficiency, and sustainability:

Advanced Materials

Researchers are exploring new materials for motor components, such as high-temperature superconductors and advanced magnetic materials.

Integrated Motor Drives

Integrating the motor, inverter, and transmission into a single unit can improve efficiency and reduce weight.

Wireless Charging

Wireless charging technology offers a convenient and seamless way to recharge EVs, eliminating the need for cables.

Solid-State Batteries

Solid-state batteries promise higher energy density, faster charging, and improved safety compared to conventional lithium-ion batteries.

AI-Powered Motor Control

Artificial intelligence (AI) is being used to optimize motor control, improving efficiency and performance.

The Impact of Electric Car Engines on the Automotive Industry

The widespread adoption of electric car engines is transforming the automotive industry in profound ways:

Shift Towards Electrification

Automakers are investing heavily in electrification, phasing out ICEs and introducing a growing range of EVs.

New Manufacturing Processes

The production of electric motors and batteries requires new manufacturing processes and supply chains.

Job Creation and Transformation

The shift to EVs is creating new jobs in areas such as battery manufacturing, charging infrastructure development, and software engineering.

Regulatory Changes

Governments around the world are implementing regulations to promote EV adoption, including emission standards and incentives.

Conclusion

Electric car engines represent a pivotal advancement in automotive technology, offering a cleaner, more efficient, and sustainable alternative to traditional ICEs. While challenges remain, ongoing innovations and investments are driving the evolution of electric motors, paving the way for a future where electric vehicles dominate the roads. The silent revolution is underway, and the electric car engine is at its heart, powering the transition to a greener and more sustainable transportation ecosystem.

“`